Information

Design Engineering for Nuclear Power Plant KOCEN Co., Ltd.

Description & Characteristics

Main Customer

- Korea Hydro & Nuclear Power Company, Ltd (KHNP)

- National Fusion Research Institute (NFRI)

- KEPCO Engineering and Construction Company, Inc (KEPCO E&C)

- Hyundai Engineering & Construction Company, Ltd (Hyundai E&C)

- Daewoo Engineering and Construction Company, Ltd (Daewoo E&C)

Product Sepcification

- Services - System design and equipment design of newly built and operating power plants - Piping design and 3D modeling of NPP etc.

- Work Scope - Design engineering of nuclear and thermal power plants - ITER (International Thermonuclear Experimental Reactor) design - System design and equipment design of NPP - Improvement design of ongoing NPP - Engineering 3D modeling of NPP - HVAC design and piping design of NPP - Piping, structural analysis and equipment integrity assessment - Staffing business of dispatched workers of CAD technician

Supplier Information

- KOCEN Co., Ltd.

- info@kocen.com

- 82-31-777-8500

- www.kocen.com

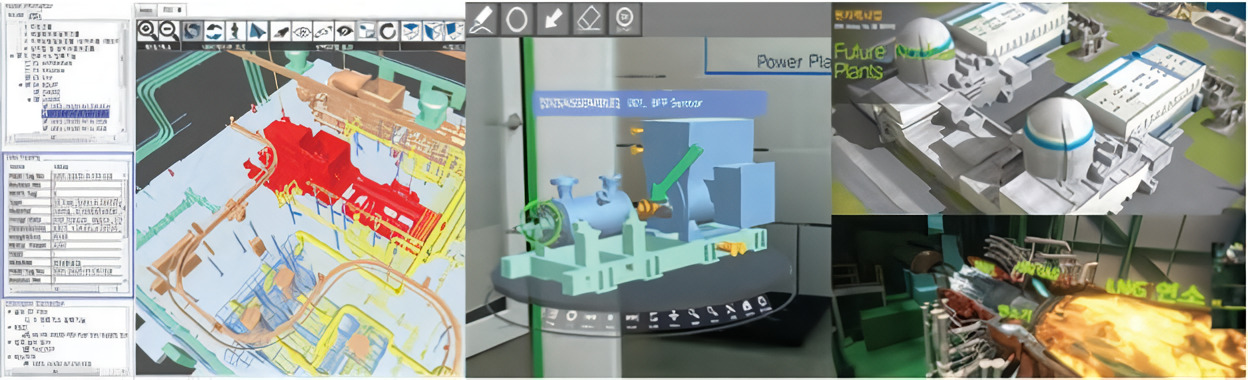

Industry 4.0 Engineering Digitalization & Solutions - AR, VR, Integrated Equipment Management System YOUL SYSTEMS INC.

Description & Characteristics

Main Customer

- CHUNCHEON ENERGY CO.,LTD / KOREA

- Korea Western Power Co., Ltd (WP) / KOREA

- Korea Hydro & Nuclear Power Company, Ltd (KHNP) / KOREA

- KEPCO Engineering and Construction Company, Inc (KEPCO E&C)

- Korea East-West Power Co., Ltd (EWP) / KOREA

- Hyundai Engineering

- Samsung Construction & Trading Corporation (Samsung C&T) / KOREA

- Korea Southern Power Co., Ltd (KOSPO) / KOREA

- Korea District Heating Corp. (KDHC) / KOREA

Supplier Information

- YOUL SYSTEMS INC.

- hskang@youlsys.co.kr

- 82-31-266-6337

- www.youlsys.co.kr

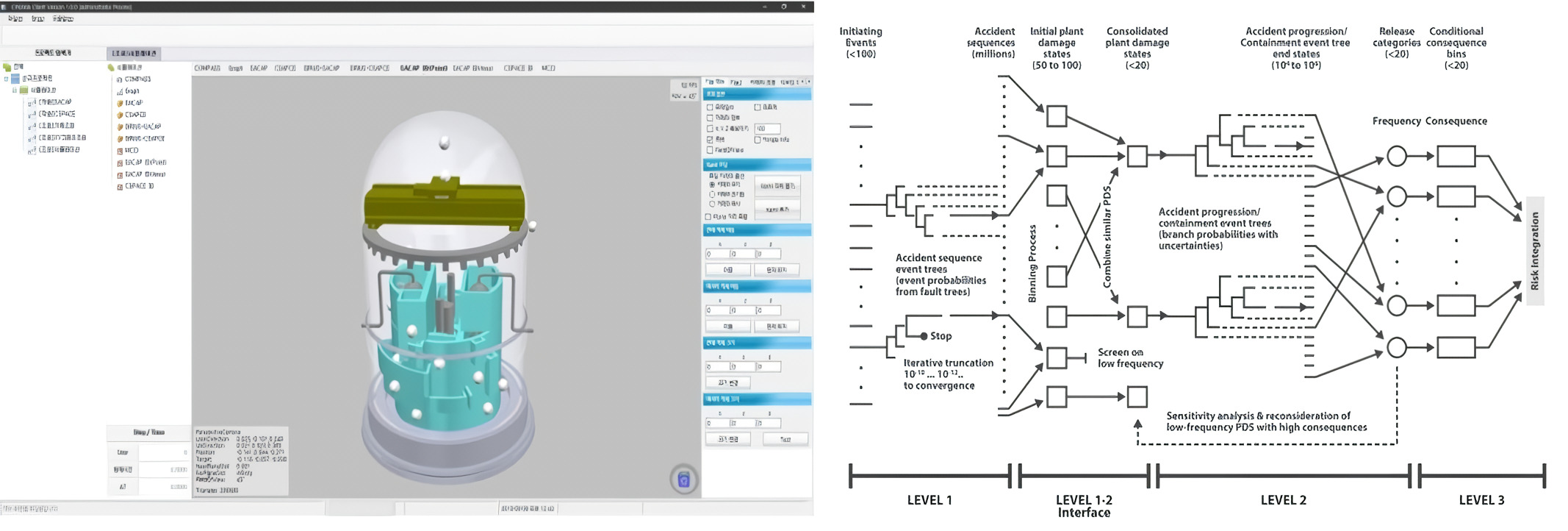

Severe Accident Analysis and Probabilistic Risk Assessment (PRA) FNC Technology Co., Ltd.

Description & Characteristics

Main Customer

- Korea Hydro & Nuclear Power Company, Ltd (KHNP) / Korea

- KEPCO Engineering and Construction Company, Inc (KEPCO E&C) / Korea

- Korea Atomic Energy Research Institute (KAERI) / Korea

- Korea Institute of Nuclear Safety (KINS) / Korea

Product Sepcification

- Expert competence of severe accident analysis codes

- MAAP, MELCOR, GOTHIC, TEXAS-V, LS-DYNA

- Development of severe accident analysis code

- Unique severe accident code for containment analysis

- Development of Severe Accident Management Guidance (SAMG)

- Full-Scope PRA including internal and external event PRA on various reactor types

- Risk-informed application experiences

Supplier Information

- FNC Technology Co., Ltd.

- viper61@fnctech.com

- 82-31-8065-5114

- www.fnctech.com

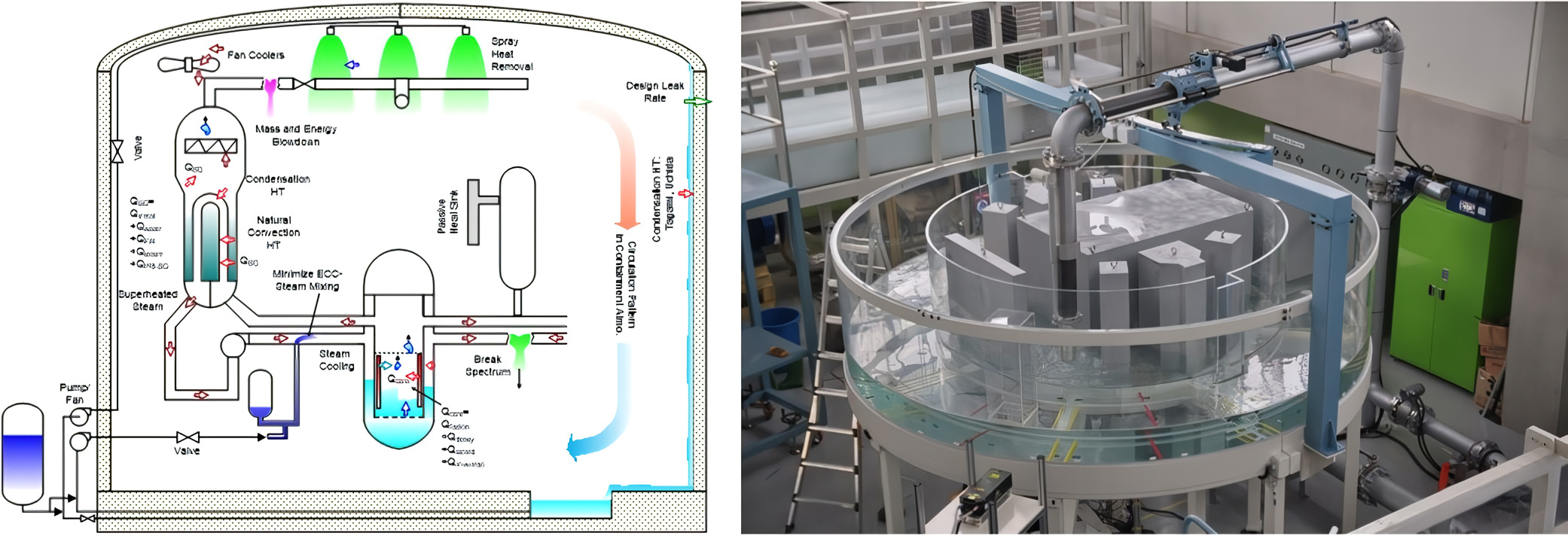

Thermal-Hydraulic(TH) Design, Analysis, and Test FNC Technology Co., Ltd.

Description & Characteristics

Main Customer

- Korea Hydro & Nuclear Power Company, Ltd (KHNP) / Korea

- KEPCO Engineering and Construction Company, Inc (KEPCO E&C) / Korea

- Korea Atomic Energy Research Institute (KAERI) / Korea

- Korea Institute of Nuclear Safety (KINS) / Korea

Product Sepcification

- Containment integrity evaluation - Containment P/T - Sub compartment pressure - Long-Term cooling performance Verification test of thermal hydraulic system in NPP - Design, build, and implementation of test facilities for safety system - Development of test methodologies and procedures

- CAP(Containment Analysis Package) - Technique-independent code domestically developed - Using state-of-art technique including 3-fields and 3-phases - Coupling with SPACE (system code developed in Republic of Korea)

Supplier Information

- FNC Technology Co., Ltd.

- viper61@fnctech.com

- 82-31-8065-5114

- www.fnctech.com

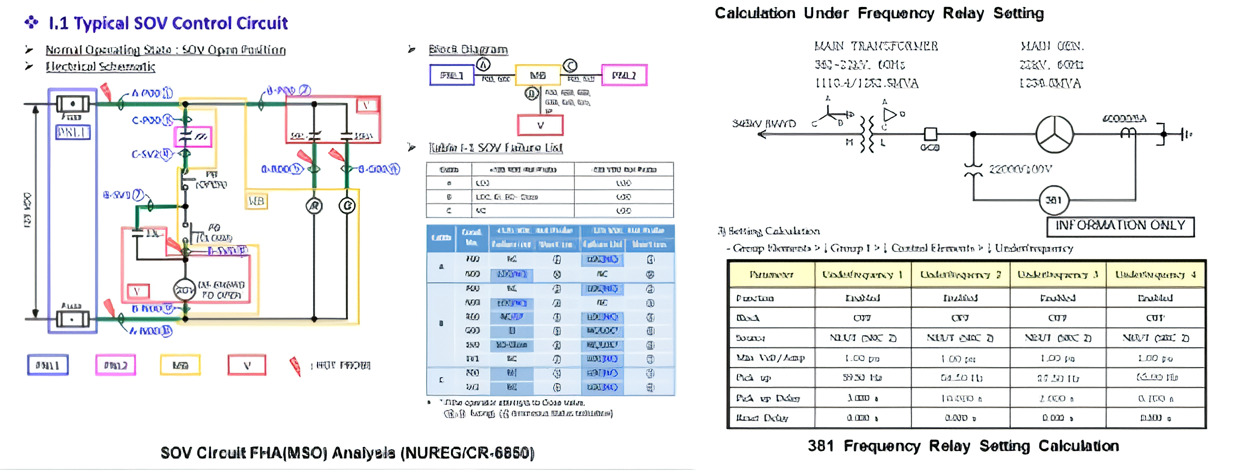

Design Changes for the Nuclear Power Plants in Operation MSO Circuit Analysis for FHA

NEI Tech Co., Ltd. (Nuclear Engineering Institute Technology Company, Ltd.)

Description & Characteristics

- Preparation of 98 design changes of electrical, instrumentation and control design for the NPP in operation. - Electrical design : Electrical System Design, Electrical Equipment Design, Electrical Circuit Design, Electrical Physical Design. - I&C design : Control System Design, Installation Design, Human Factors Engineering Design.

- Electric circuit analysis of MSO(Multiple Spurious Operation) for FHA of NPP in operation.

- Certification of Completion - 2013 EPRI / NRC-RES, Fire Probabilistic Risk Assessment Session 2

Main Customer

- Korea Hydro & Nuclear Power Company, Ltd.(KHNP) / KOREA - 98 Design Changes for the Nuclear Power Plants in Operation in 2018

- Hyundai Engineering and Construction Company, Ltd. (Hyundai E&C) / Korea Hydro & Nuclear Power Company, Ltd. (KHNP) / KOREA - 40 Design Changes for the Nuclear Power Plants in Operation in 2016

- Professional Nuclear Engineering(PNE)/Korea Hydro & Nuclear Power Company, Ltd.(KHNP) /KOREA - Electric circuit analysis of MSO for Hanul NPP#1,2 & Kori NPP #2 in operation

Product Sepcification

- Calculation - Electrical Power Capacity, Short Circuit Current, Load Flow & Voltage Drop, Relay Setting & Coordination, Lighting Illumination, Ground Resistance.

- Cathodic Protection Design, Lightning Design, Heater tracing Design, Communication Design, Security System Design, Fire Detector System Design.

- Physical Design - Panel Installation, Instrumentation installation, Cable Sizing and Routing, Cable Tray & Conduit Installation.

- Human Factors Engineering

- Fire Hazard Analysis (FHA) - Electric Circuit Analysis for MSO (Multiple Spurious Operation)

Supplier Information

- NEI Tech Co., Ltd. (Nuclear Engineering Institute Technology Company, Ltd.)

- nei@neitech.co.kr

- 82-2-889-9210

- www.neitech.co.kr

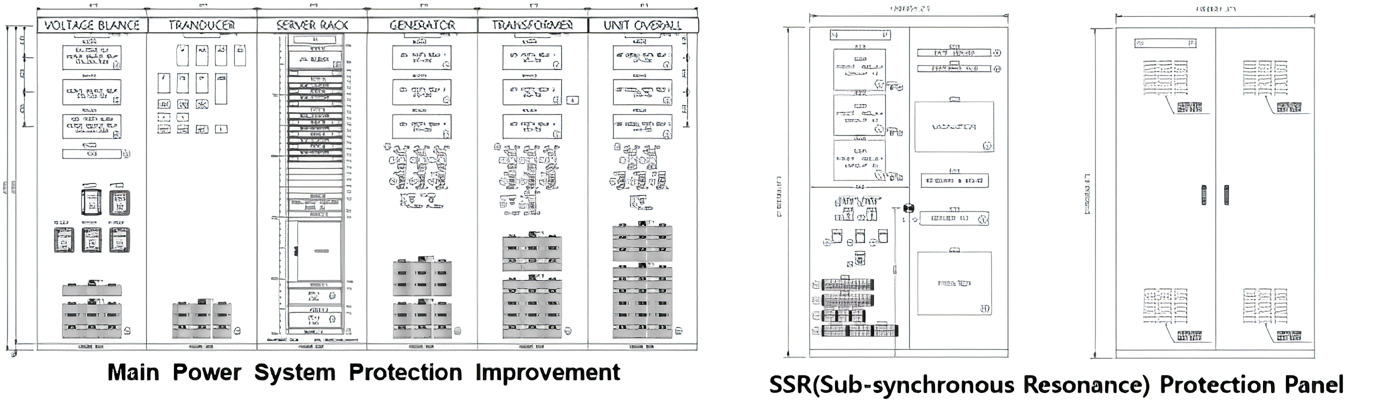

Improvement of Main Power System Protection Equipment Engineering of SSR Protection Panel for Generator shaft

NEI Tech Co., Ltd. (Nuclear Engineering Institute Technology Company, Ltd.)

Description & Characteristics

- Applying a lot of experience for improving the electrical protection system of NPPs.

- 345kV Switchyard System Design & Engineering. Such as Electrical Equipment and Relay Protection .

- Main Power System Protection Design & Engineering. Such as Generator, Transformer and Excitation System, GCB, GIB. etc,.

- Design and engineering for SSR (Sub-synchronous Resonance) protection for the first time in Korea using PSCAD Program.

Main Customer

- Korea Hydro & Nuclear Power Company, Ltd.(KHNP)/ KOREA - Engineering SSR Protection Relay Panel for Generator shaft Protection for Hanul NPP #1~6

- Hyundai Engineering and Construction Company, Ltd. (Hyundai E&C) / Korea Hydro & Nuclear Power Company, Ltd.(KHNP) /KOREA 1. Improvement for Wolsung NPP #1 - Generator and Excitation System 2. Improvement for Hanul NPP #5,6 - Generator and Main Power Protective Relay Panel

Product Sepcification

- Calculation - SSR Protection for Generator, Main Power System Protection, Electrical Power Capacity, Short Circuit Current, Load Flow & Voltage Drop, Relay Setting & Coordination, Transient Stability, Seismic Capacity & Structure Integrity with Civil Consortium - Using electric program : PSCAD and ETAP program

- Physical Design - Cable Sizing and Routing, Cable Tray & Conduit Installation, Panel Installation

- Technical Specification, Bid Evaluation and Vendor Print Reviews for Protective Relay Panel

- Human Factors Engineering

Supplier Information

- NEI Tech Co., Ltd. (Nuclear Engineering Institute Technology Company, Ltd.)

- nei@neitech.co.kr

- 82-2-889-9210

- http://www.neitech.co.kr/

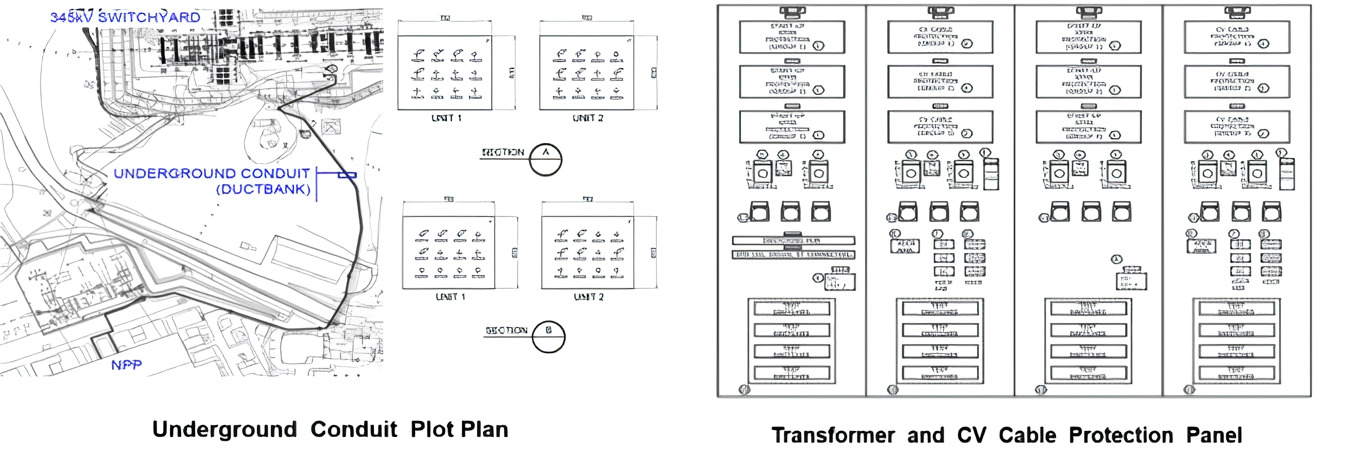

Improvement of NPPs Switchyard & Power Transmission Line NEI Tech Co., Ltd. (Nuclear Engineering Institute Technology Company, Ltd.)

Description & Characteristics

- Design Change Report - Design of transmission tower and 345kV cables to connect the transmission lines of NPPs to the new switchyard. - Circuit design for control and protection of switchyard system.

- Technical specifications, Bid evaluations and Vendor print reviews for protective relay panel

Main Customer

Product Sepcification

- Calculation - Electrical Power Capacity, Short circuit Current, Load Flow & Voltage Drop, Relay Setting & Coordination - Using Electric Program : ETAP

- Physical Design - Panel Installation, Cable Sizing and Routing, Cable Tray & Conduit Installation

- Technical specifications, Bid evaluations and Vendor print reviews for protective relay & panel

- Human Factors Engineering

Supplier Information

- NEI Tech Co., Ltd. (Nuclear Engineering Institute Technology Company, Ltd.)

- nei@neitech.co.kr

- 82-2-889-9210

- www.neitech.co.kr

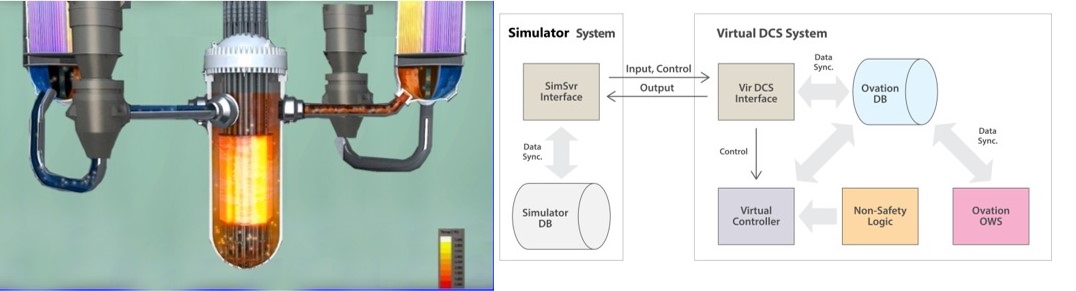

Nuclear Power Plant Simulator Technology FNC Technology Co., Ltd.

Description & Characteristics

- FNC is a all-round player in operator training simulator for nuclear power plant and offering total solutions for the development and maintenance of the simulators.

- FNC has all kind of core technologies to develop and modify simulators, such as development of reactor core & thermal-hydraulic model, plant system model, and real system emulation interface.

- For the maintenance and update of simulators, FNC has abundant experiences to resolve issues and discrepancies due to the upgrade of systems or version differences, and also, to provide training services to the administrators or maintenance personnel.

Main Customer

Product Sepcification

Supplier Information

- FNC Technology Co., Ltd.

- viper61@fnctech.com

- 82-31-8065-5114

- www.fnctech.com

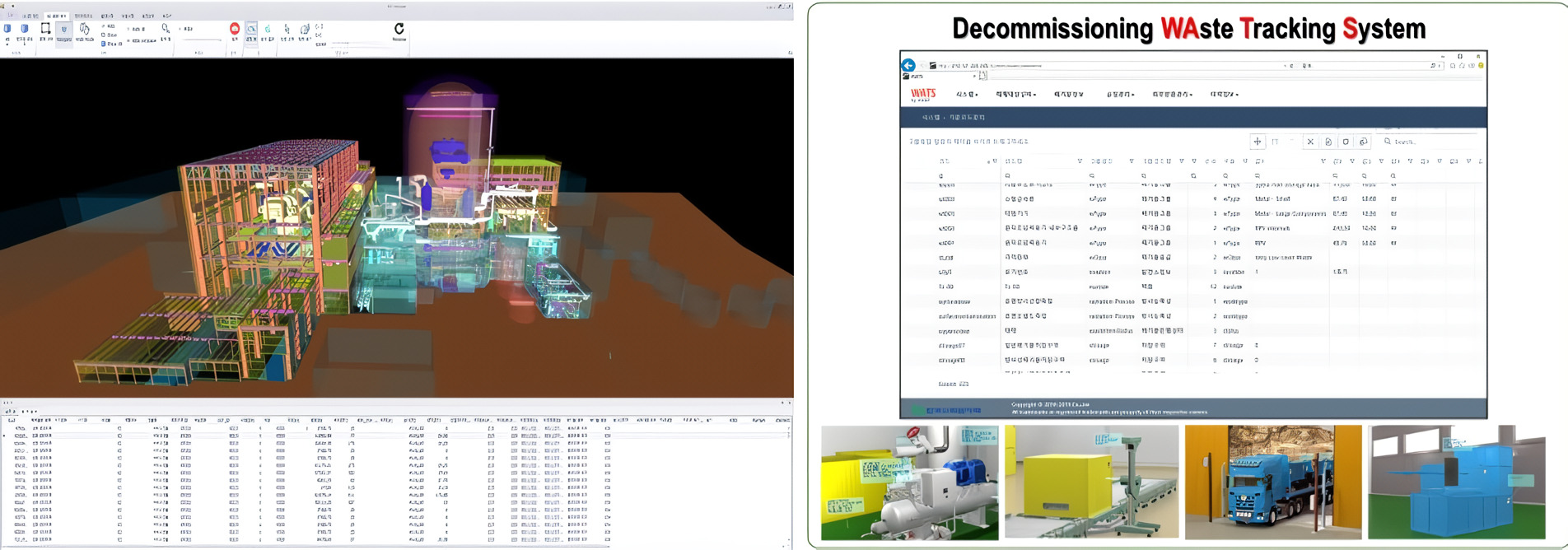

1. 5D BIM based evaluation software for decommissioning inventory, cost and processing

2. Decommissioning Waste Tracking Systm

Korea Nuclear Engineering Services, Co., Ltd.

Description & Characteristics

- BIM-based 5D Program for decommissioning schedule, waste quantity and cost - 3D BIM modeling for site-specific plant inventories - Development of algorithms for automatic calculation of waste quantity and decommissioning cost - Integration of 3D BIM model, decommissioning schedule and cost

- Decommissioning Waste Tracking System - Development of decommissioning waste history/ transaction tracking system to trace all the information necessary for safe and economic waste management - Development and application of the site-specific RFID tags to overcome challenging conditions expected in decommissioning activities - Development of web-based programs

Main Customer

Certification

- ISO9001

- Application of QA system as per KEPIC-QAP, ASME NQA-1

- Operation of QA procedures/Design control procedures/ Operation guides

- Certified by Korea Hydro & Nuclear Power Co. as Quality class-Q services

Supplier Information

- Korea Nuclear Engineering Services, Co., Ltd.

- Wabmail@kones21.com

- 82-2-2057-4003

- www.kones21.com

Engineering Service for Operating Nuclear Power Plant Hyundai Engineering Co., Ltd.

Description & Characteristics

Main Customer

Product Sepcification

- Act and Law for Nuclear Industry of Korea

- APR1400 / OPR1000 (standard nuclear power plant of Korea)

Supplier Information

- Hyundai Engineering Co., Ltd.

- 82-2-2134-1114

- www.hec.co.kr

Fire Protection Engineering Korea Fire Protection Engineering Co., Ltd.

Description & Characteristics

Main Customer

- Design of fire extinguishing facilities in temporary storage of Hanbit 3 and 4 and fire control licensing service, KEPCO Engineering and Construction Company, Inc (KEPCO E&C) / KOREA

- Design service of Kori-2 Evacuation Path and Fire Control Path, KEPCO Engineering and Construction Company, Inc (KEPCO E&C) / KOREA

- Performance Evaluation of Sprinkler Facility in Emergency Diesel Generator Room, Korea Hydro & Nuclear Power Company, Ltd (KHNP) / KOREA

- Detailed Design Service of Firefighting Facilities in the Storage System of Wolseong Headquarters, KEPCO Engineering and Construction Company, Inc (KEPCO E&C) / KOREA

- Detailed Design of System Design Fire Control Facility in 2017, KEPCO Engineering and Construction Company, Inc (KEPCO E&C) / KOREA

Product Sepcification

- Notice of Nuclear Safety Act, Enforcement Decree, Enforcement Rules and Nuclear Safety Commission

- Safety Rules Guidelines of the Korea Institute of Nuclear Safety (KINS/GR)

- Final Safety Analysis Report of Power Plant(FSAR)

- American Iron & Steel Institute(ANSI)

- Korea Electric Power Industry Code(KEPIC)

- National Fire Protection Association(NFPA)

- Domestic Act on the Safety Management of Hazardous Goods

- Domestic Fire Protection Act (including national fire safety standards)

Supplier Information

- Korea Fire Protection Engineering Co., Ltd.

- kfubis@kfubis.com

- 82-2-2023-5000

- www.kfubis.com

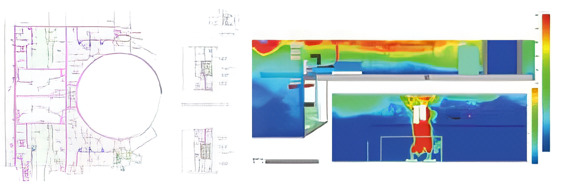

Fire Protection Safety Analysis, Design STANDARD Testing & Engineering Inc.

Description & Characteristics

- Comprehensive Fire Safety Assessment of Nuclear Power Plants base on deterministic and performance-based methodologies(Fire Hazard Analysis, Multiple Spurious Operation Analysis, Fire Modeling, Fire Probabilistic Risk Assessment, Fire Barrier Penetration Seals Evaluation, External Fire Evaluation etc.)

- Comprehensive Fire Safety Assessment and Fire Protection System Design of Building/Plant.

Main Customer

- Korea Hydro & Nuclear Power Company, Ltd (KHNP) / Korea

- KEPCO Engineering and Construction Company, Inc (KEPCO E&C) / Korea

- Korea Atomic Energy Research Institute (KAERI) / Korea

- Korea Institute of Nuclear Safety (KINS) / Korea

- Korea Energy Technology Evaluation and Planning / Korea

Product Sepcification

- Fire Hazard Analysis Program : Standard FHA Tool

- Fire Safe Shutdown Analysis Program : Standard FHA Tool & Safe Shutdown Analysis Program

- Fire Simulation Program : FDTs, FDS, CFAST, etc.

- Wildfire/Evacuation Simulation Program : FARsite, EXODUS, Pathfinder etc.

Supplier Information

- STANDARD Testing & Engineering Inc.

- ljh@stdte.co.kr

- 82-42-867-6453

- www.stdte.co.kr

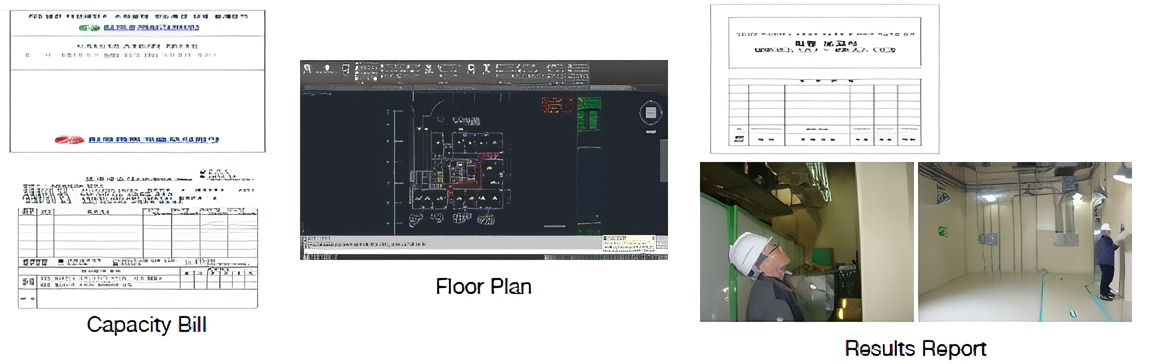

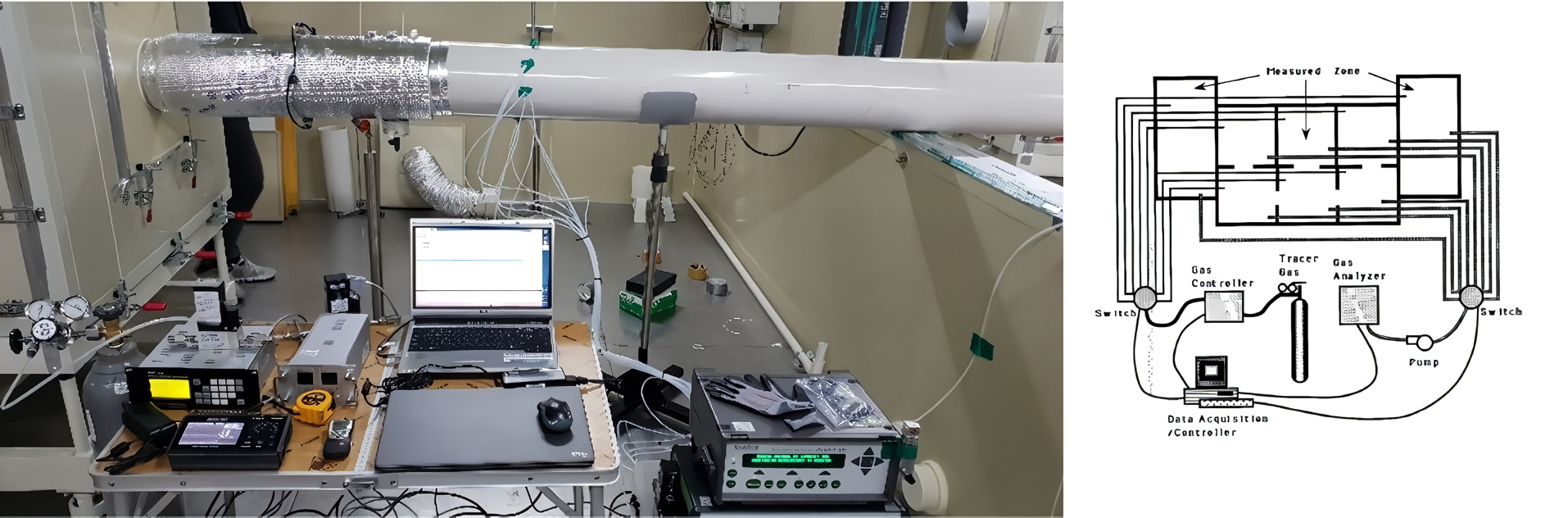

Main Control Room Habitability Assessments (CRE In-leakage Test) STANDARD Testing & Engineering Inc.

Description & Characteristics

Main Customer

- Korea Hydro & Nuclear Power Company, Ltd (KHNP) - Barakah Nuclear Power Plant Unit 2 in UAE

- Korea Hydro & Nuclear Power Company, Ltd (KHNP) - Shin-Wolsong Nuclear Power Plant Unit 1 and 2 in Korea

- Korea Hydro & Nuclear Power Company, Ltd (KHNP) - Hanul Nuclear Power Plant Unit 5 and 6 in Korea

- Kori Radiological Disaster Prevention Center (KINS)

- Chin Shan/Kuosheng/Maanshan Nuclear Power Plant in Taiwan / TPC

Product Sepcification

- ASTM E741-11 Standard Test Method for Determining Air Change in a Single Zone by Means of a Tracer Gas Dilution

- ASTM E2029-11 Standard Test Method for Volumetric and Mass Flow Rate Measurement in a Duct Using Tracer Gas Dilution

- Reg. Guide 1.197 Demonstrating Control Room Envelope Integrity at Nuclear Power Reactors, May 2003

- NEI 99-03(Rev.1) Control Room Habitability Guidance

- 10 CFR 50 Appendix A. GDC 19 Control Room

Supplier Information

- STANDARD Testing & Engineering Inc.

- ljh@stdte.co.kr

- 82-42-867-6453

- www.stdte.co.kr