Korean Nuclear Industry

- European

APR1400 -

European Standard Design

The European APR1400 is a Gen 111+ Pressurized Water Reactor(PWR), with a large capacity over 1,500 MW of electrical power to comply with European safety and performance requirements.

Based on the proven design and operating experience of the OPRIOOO and the APR1400, up-to-date design technologies have been incorporated to enhance plant safety with excellent performance.

EU-APR Major Parameters

GENERAL

PLANT DATAGross Power Output 1,520 MWe NSSS Thermal Power 4,000 MWth Design Lifetime 60 years Seismic Design Basis DBE 0.25g REACTOR

COREActive Core Length 3.81 m Core Diameter 3.65 m Average Heat Flux at 100% Power 589.1 kW/m2 Number of Fuel Assemblies 241, 17×17 Number of

Control Element Assemblies76 Full Strength,

17 Part StrengthFuel Cycle Length 18 to 24 months REACTOR

COOLANT

SYSTEMNumber of Loops 2 Operating Pressure 15.5 Mpa Inlet Temperature 290.6℃ Outlet Temperature 323.9℃

- Enhanced Safety

-

Improved Safety Systems

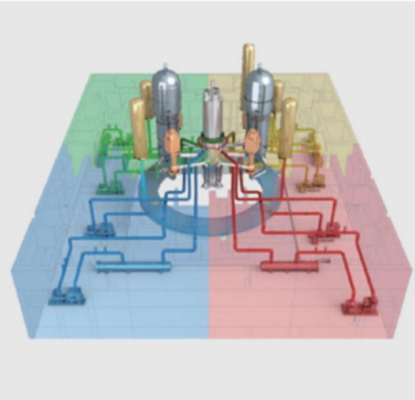

4 Independent Train Safety Injection System

- Provides borated water to core with Active & Passive Components

- Fluidic Device installed at the bottom of the Safety Injection Tank (SIT) passively and efficiently controls the safety injection flow into the core

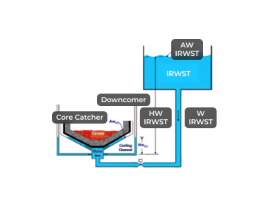

Safety Injection System (SIS) uses injecting water from In-Containment Refueling Water Storage Tank (IRWST)

4 Train Safety Injection System

Mitigation of Severe Accident

Passive Autocatalytic Recombiner(PAR)

- Limit hydrogen concentration

- Prevent hydrogen detonation

Severe Accident Containment Spray System(SACSS)

- Control containment pressure & remove fission products during Severe Accidents(SA)

- Dedicated supporting systems:

- Severe Accident Dedicated Component Cooling Water System(SACCWS)

- Severe Accident Dedicated Essential Service Water System(SAESWS)

Emergency Reactor Depressurization System(ERDS)

- Reduces the RCS pressure before reactor vessel breach

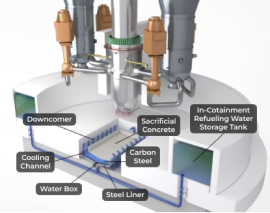

Passive Ex-Vessel Corium Retaining & Cooling System(PECS)

- Installed in the reactor cavity to retain & cool down the molten core debris

- Retain corium in the Ex-vessel core catcher & achieve a long term safe state

PAR

PECS

Core Catcher

Catcher Diverse Design Features

Emergency Boration System(EBS)

- Inject highly concentrated borated water into RCS

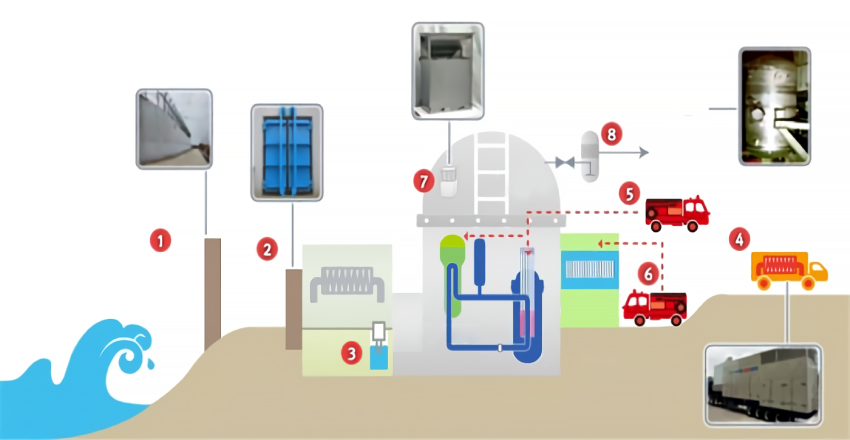

Provisions for Beyond Design Basis External Events

Designed to assure core cooling, spent fuel cooling, containment integrity beyond Design Basis External Events(BDBEE) (as Fukushima Event)

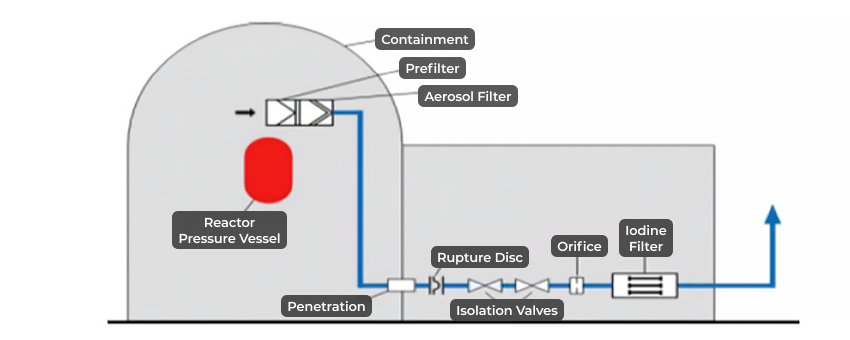

Containment Filtered Vent System(CFVS)

- Ensure containment integrity during extreme conditions by relieving pressure in a controlled manner

Aircraft Crash Protection Design

- Secondary containment provides barrier against a large, commercial aircraft crash

- Strengthened external wall of the containment building & auxiliary building

- Separation of other safety important buildings

Aircraft Crash Shield Wal

Aircraft Crash Protection

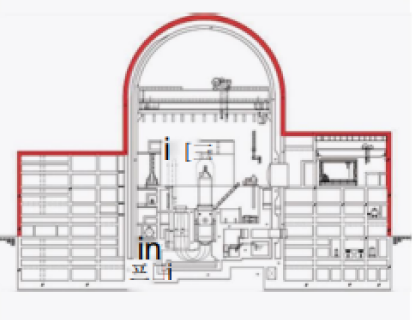

Double Containment Building

Primary Containment Structure

- Keep the pressure boundary by liner plate

- Provide biological shielding & reduce the radioactive release

Aircraft Crash Protection Design

- Fully envelop the primary containment

- Preserve structural integrity against airplane crash

- Secondary containment HVAC system

Double Containment Building

Enhanced Seismic Resistance

Safety-Related Buildings & Structures withstand Seismic Events with 0.25g PGA

- Envelops Most Sites with Different Types of Rock & Soil

- Excellence in

Construction -

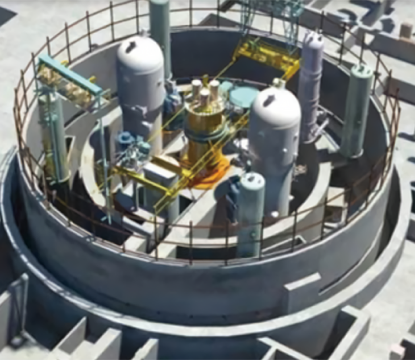

Equipment Modularization

Pre-fabrication of modules helps the reduction of field work & on-site labor congestion

- Approximately 80 items selected for modularization

- Modules can Be lifted & installed using a large capacity crane

Modularized Reactor Internals

Top-Down Method

Use the top-down method with large capacity cranes to reduce the construction period

Large Capacity Cranes

Construction Schedule

Target construction period of the first plant set to be 57 months

From the first concrete pouring to commercial operation

- Outstanding

Performance -

60 Years of Lifetime with Availability over 92%

Convenient Operation & Maintenance

Removable shield blocks & covers lower the radiation level to allow personal access to the containment during power operation

Integrated Head Assembly(IHA) & permanent refueling pool seal simplify refueling works

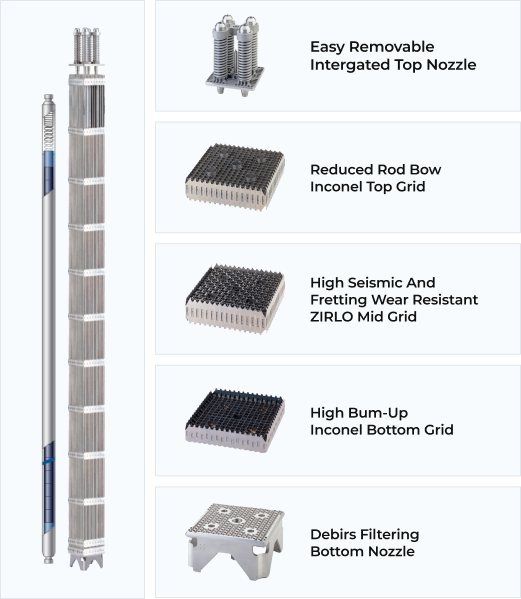

High Performance Fuel Assembly

Utilizes HIPER16 TM, an advanced fuel assembly with high thermal performance & enhanced seismic resistance

Provides a thermal margin greater than 10%

Increased discharge burn-up enables refueling cycles to be flexible from 18 to 24 months

Integrated Head Assembly

PLUS 7

Grid Following Capability

Daily load-following & frequency control capacity

- Enables the plant to respond to power demand variations from the grid