Korean Nuclear Industry

- APR1400

-

US NRC Certified Design

The APR1400 is a Gen 111+ large capacity Pressurized Water Reactor(PWR), generating 1,400

MW of electrical power to comply with US NRC regulations.Total 5 Units of APR1400 is now in operation both in Korea(4 units) and UAE (l Unit),& 4 units in Korea and 3 units in UAE are under construction. By adopting the proven and advanced design features based on technology enhancement, the APR1400 achieved the Design

Certification(DC)from the US NRC in August 2019.By achieving NRC approval - the international "Gold Standard - for design and safety - the

APR1400 brings improved public confidence and internationalreputation.EU-APR Major Parameters

GENERAL

PLANT DATAGross Power Output 1,400 MWe Thermal Power 3,983 MWth Design Lifetime 60 years Seismic Design Basis DBE 0.3g REACTOR

COREActive Core Length 3.81 m Core Diameter 3.65 m Average Heat Flux at 100% Power 589.1 kW/m2 Number of Fuel Assemblies 241, 16×16 Number of

Control Element Assemblies81 Full Strength,

12 Part StrengthFuel Cycle Length 18 REACTOR

COOLANT

SYSTEMNumber of Loops 2 Operating Pressure 15.5 Mpa Inlet Temperature 290.6℃ Outlet Temperature 323.9℃

- Enhanced Safety

-

Improved Safety Systems

4 Independent Train Safety Injection System

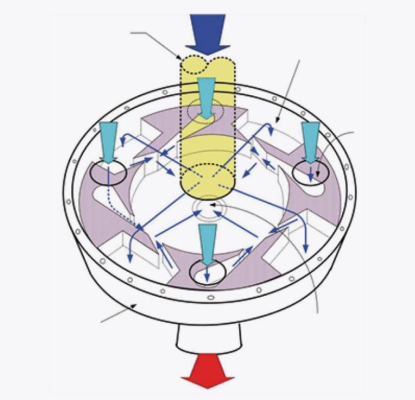

- Provides borated water to core with Active & Passive Components

- Fluidic Device installed at the bottom of the Safety Injection Tank (SIT) passively and efficiently controls the safety injection flow into the core

Safety Injection System (SIS) uses injecting water from In-Containment Refueling Water Storage Tank (IRWST)

4 Train Safety Injection System

Fluidic Device

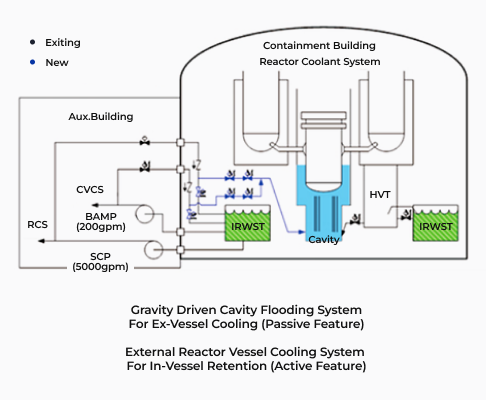

Mitigation of Severe Accident

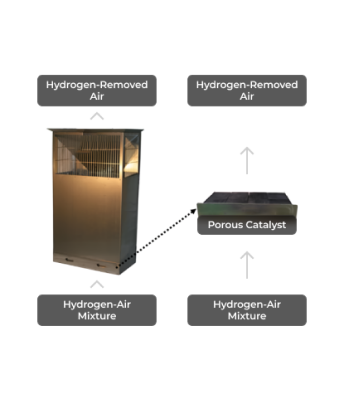

Passive Autocatalytic Recombiner (PAR) & Hydrogen Ignitor

- Limit Hydrogen Concentration

- Prevent Hydrogen Detonation

Improved Performance of Containment Spray System

- Emergency Containment Spray Backup (ECSB) system guarantees the integrity of containment by cooling containment for 48 Hours from one full day after a core melt down

Cavity Flooding System & Corium Chamber

- Cavity Flooding System prevents basement melt-through

- Corium Chamber cools molten corium inside the containment

Rapid Depressurization System

- Safety Depressurization & Vent System, SDVSRapidly reduces the pressure of the reactor coolant system when the pressurizer spray is unavailable during shutdown cooling

* The Pilot Operated Safety Relief Valves (POSRV) are employed to enable precise operation & easy Maintenance - Emergency Reactor Depressurization System, ERDS Applied In-Vessel Retention & Ex-Reactor Vessel Cooling(IVR-ERVC) System

Passive Autocatalytic Recombiner

Passive Autocatalytic Recombiner

Provisions for Beyond Design Basis External Events

Enhanced design against Beyond Design Basis External Events(BDBEE),

incorporating Fukushima accident lessons learned- Phased core and spent fuel pool cooling strategy

- Enhanced containment capability to LOCA

- Diverse & flexible supporting system

- Enhanced design and mitigation strategies to cope with loss of large area accident due to explosion and fire

Designed to take into account potential impact of a large, commercial aircraft

crash, accordance with 10 CFR 50.150 & regulatory Guide 1.217

Tsunami Barrier

Waterproof Door

- Advanced

Technology -

Fully Digitalized I&C System with Diverse Platforms

Independent & diverse actuation system provided to cope with software Common Cause Failures(CCFs) of the safety-related I&C systems

Fully digitalized Man-Machine Interface System(MMIS) installed in Main Control Room(MCR)

- Allows operators focus on their work in a user friendly & unobstructed way which enhances the reliability of plant operation

MMIS / Main Control Room

Seismic Analysis Enveloping Multiple Sites

Has capacity to deal with wide range of site-specific parameters

- ex. Site shear wave velocity profiles, ambient temperatures, wind speeds

Hard rock high frequency response spectra covers approx. 80% of ground motion response spectra of central/eastern US NPP sites

Radiation Protection Design

Ensures the radiation exposure to workers and public during normal plant operations & postulated accident conditions within the regulatory limit & maintained As Low As Reasonably Achievable(ALARA)

- Achieved by the use of low corrosive materials, RCS chemistry control, high fuel performance, the treatment of radioactive materials, the monitoring of releases, provision of sufficient radiation shielding and prevention, the detection and collection of contamination

Minimization of Contamination/ Radwaste Generation

Minimize the Use of Embedded and Buried Piping, Provides Leak Detection Instrumentation, Drainage Trenches, Double-Walled Piping for All Radioactive and Potentially Radioactive Systems

Comply with Design Requirements of 10 CFR 20.1406 & Regulatory Guide 4.21

- Excellence in Construction

-

Equipment Modularization

Pre-fabrication of modules helps the reduction of field work & on-site labor congestion

- Approximately 80 items selected for modularization

- Modules can be lifted & installed using a large capacity crane

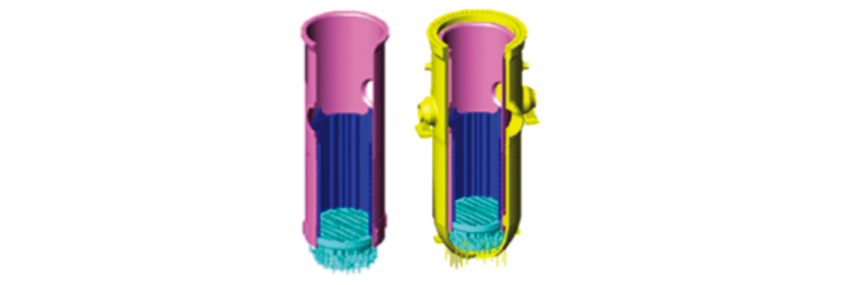

Representatively, the internal components of the reactor are fabricated in two parts

- Integrating instead of the use of on-site Welding

Modularized Reactor Internals

Top-Down Method

Use the top-down method with large capacity cranes to reduce the construction period

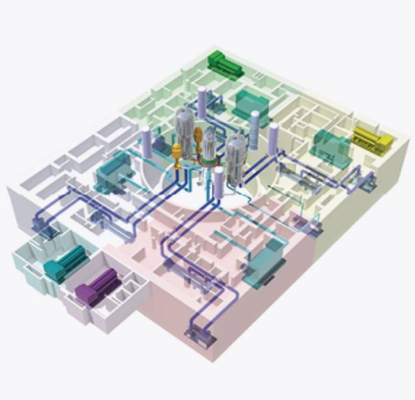

3D Design Method

Prevents errors & results in reduced construction costs

Allow engineers enhance constructability & maintainability of the plant

- By utilizing various design output such as drawing & a list of materials through the verified 3D CAD Model

3D Modelling Images

- Outstanding

Performance -

60 Years of Lifetime with Availability over 90%

Convenient Operation & Maintenance

Independent & diverse actuation system provided to cope with software Common Cause Failures(CCFs) of the safety-related I&C systemsRemovable shield blocks & covers lower the radiation level to allow personal access to the containment during power operation

Integrated Head Assembly(IHA) & permanent refueling pool seal simplify refueling works

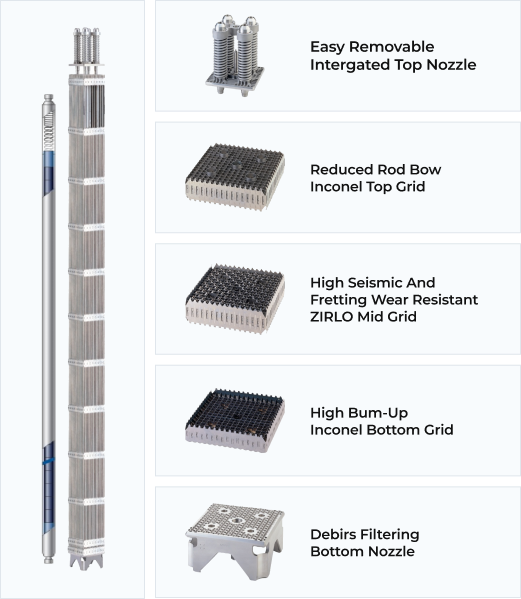

High Performance Fuel Assembly

Utilize Plus 7TM, An Advanced Fuel Assembly with High Thermal Performance etc.

A High Burnup Capability of 55 GWD/MTU(batch Average)

More than 5,000 Plus7TM Fuel Assemblies Have Been Commercially Supplied & Operated in NPPs as of 2017

Integrated Head Assembly

PLUS 7